DIE AND MOLD

Die And Mold

In the Die and Mold industry, precision is everything. We specialize in Sheet Metal Punch Dies and Sheet Metal Forming Dies, proudly operating as a Sheet Metal Die Manufacturer, serving Lahore and Pakistan. Our expertise also spans plastic injection parts manufacturing, contributing significantly to molding design. In the automotive sector, we excel in automotive plastic injection molding, crafting top-quality tools like Hot Runner Mold with the use of D2 Die Steel. At the heart of the Mold And Die Industry, we are committed to innovation and engineering excellence, solidifying our reputation as a reliable Die maker In Lahore and Die maker In Pakistan.

Sheet Metal Die

As a prominent Sheet Metal Die Manufacturer, our expertise extends beyond local boundaries. With a strong presence as a Die Maker in Lahore and serving clients throughout Pakistan, our commitment to precision and innovation shines through in every project we undertake. As a Die Maker in Lahore, we take pride in our local roots and global reach, ensuring that our sheet metal dies meet the highest industry standards. Our dedication to quality and craftsmanship has established us as a trusted Die Maker in Pakistan, while our reputation as a Sheet Metal Die Manufacturer speaks to our excellence in crafting precision tools for a wide range of applications. We also manufacturing Sheet Metal Punch Dies, Sheet metal forming dies etc. Whether you’re in Lahore or any part of Pakistan, our sheet metal dies are crafted to perfection, catering to the diverse needs of businesses across the country.

Plastic Injection Parts Manufacturer

As a leading Plastic Injection Parts Manufacturer, we specialize in producing high-quality components that meet the exacting standards of various industries. With a wealth of experience and cutting-edge technology, we take pride in our reputation as a trusted supplier of plastic injection parts. Our commitment to precision and quality ensures that each component we manufacture is not only durable but also consistently meets the stringent requirements of our clients. At our facility, we employ state-of-the-art machinery and employ skilled technicians to deliver exceptional results. When it comes to plastic injection parts manufacturing, our dedication to excellence is unmatched. Trust us as your reliable Plastic Injection Parts Manufacturer for all your component needs.

Molding Design

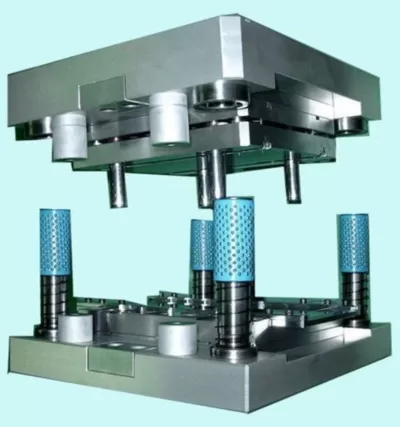

Molding design plays a pivotal role in the manufacturing process, influencing the quality and efficiency of the final product. At our company, we specialize in Molding Design services that are tailored to meet the unique needs of our clients. Our team of experienced designers employs cutting-edge techniques and software to create precise and effective molds. Whether it’s for plastic, metal, or composite materials, our molding designs are optimized for efficiency and cost-effectiveness. We understand that a well-crafted mold design is the foundation of successful manufacturing, ensuring consistent and reliable production. Partner with us for your molding design needs, and experience the difference expertise makes in achieving superior results.

Automotive Plastic Injection Molding

Automotive plastic injection molding is at the core of innovation and efficiency in the automotive industry. Our expertise in automotive plastic injection molding positions us as a leading provider of precision components for vehicles. From interior trims to under-the-hood parts, we excel in manufacturing high-quality automotive components through advanced injection molding techniques. Our commitment to using top-grade materials and cutting-edge technology ensures that the final products meet stringent industry standards for durability, safety, and performance. With a keen focus on automotive plastic injection molding, we contribute to the evolution of automobiles, creating lightweight, durable, and cost-effective solutions. Partner with us to drive your automotive innovations forward through expert plastic injection molding.

Stapler Die

For over a decade, Lucky Engineering Works has been a cornerstone of Stapler Die manufacturing in Pakistan. Our dedicated team of skilled Die makers in Pakistan has consistently delivered precision-engineered Stapler Dies that meet and exceed industry standards. Renowned for our commitment to excellence and reliability, we are the trusted choice for businesses across the nation. In a competitive market, our expertise shines as a testament to Pakistan’s manufacturing prowess. Whether for stationery, packaging, or industrial applications, our Stapler Dies are celebrated for their precision and performance, making us the preferred partner for businesses seeking quality solutions in Pakistan.

Punch Dies

When it comes to precision crafting of paper punches, Lucky Engineering Works is a leading name in the industry. Specializing in the production of high-quality Paper Punch Dies, we ensure accuracy and durability with every punch. As a trusted manufacturer, we are committed to delivering top-notch products that meet the stringent demands of businesses and craft enthusiasts alike. Our dedication to precision craftsmanship has made us an essential contributor to the stationery and crafting sectors. Whether it’s for personal use or industrial applications, the reliability and performance of Paper Punch Dies from Lucky Engineering Works are a testament to our manufacturing expertise.

Compound Dies

Compound dies are the unsung heroes of the metal fabrication industry, finding essential use in various sectors like automotive, electronics, and more. These specialized tools, often crafted by skilled manufacturers, enable the simultaneous cutting and forming of intricate shapes in metal sheets. In the automotive industry, compound dies play a pivotal role in shaping precise metal components, contributing to vehicle durability and performance. Similarly, in the electronics sector, they aid in the production of intricate metal parts, ensuring the reliability of electronic devices. At Lucky Engineering Works, we excel in designing and producing compound dies that meet the diverse needs of these industries, reflecting our commitment to precision engineering.

Cutting Die

Cutting dies are vital tools employed in various industries to craft precision components with remarkable accuracy. These dies excel in cutting materials such as metals, plastics, and fabrics into intricate shapes. In the automotive industry, cutting dies are instrumental in producing parts like gaskets, seals, and interior upholstery components. Additionally, they play a pivotal role in crafting intricate electrical connectors and housing components for the electronics sector. At Lucky Engineering Works, we specialize in designing and manufacturing cutting dies that meet the rigorous demands of these industries. Our commitment to precision ensures that each component produced using our cutting dies adheres to the highest quality standards, contributing to the reliability and performance of diverse products.

Forming Die

Forming dies are indispensable tools in the world of manufacturing, capable of shaping materials with remarkable precision. These versatile dies excel in transforming a variety of materials, including metals, plastics, and ceramics, into intricate and accurate components. Whether it’s in the automotive industry, where they contribute to the creation of chassis components, or in the realm of consumer electronics, where they are instrumental in producing finely detailed connectors and housing components, forming dies play a crucial role in diverse applications. At Lucky Engineering Works, we specialize in designing and manufacturing forming dies that meet the highest standards of precision and quality. Our commitment to excellence ensures that the components created using our forming dies stand out for their reliability and performance across a wide range of industrial and manufacturing sectors.

Progressive Die

Progressive dies are versatile tools known for their precision in shaping and cutting materials efficiently. In the aerospace industry, they are crucial for crafting intricate components that enhance aviation safety and performance. Simultaneously, the medical device sector relies on progressive dies to manufacture precise parts for diagnostic equipment. At Lucky Engineering Works, we specialize in designing and producing progressive dies, ensuring components meet the highest industry standards for precision and quality. Our commitment to excellence extends across diverse industrial sectors, delivering reliable, high-performing parts for a wide range of applications.

Multi Cavity Mold

Multi-cavity molds are pivotal in streamlining manufacturing processes across diverse industries. These molds enable the simultaneous production of multiple identical parts, offering remarkable efficiency gains and cost savings. In the consumer goods sector, they are instrumental in mass-producing items like bottle caps and closures, meeting the demands of a competitive market. Additionally, multi-cavity molds find widespread use in the packaging industry, facilitating the rapid production of identical containers to fulfill consumer needs promptly. At Lucky Engineering Works, we specialize in tailoring multi-cavity molds to our clients’ specific requirements, emphasizing precision and efficiency. Our dedication to innovation empowers businesses to optimize their manufacturing processes, consistently delivering high-quality products to the market while reducing production costs.